-

Chocolate Production

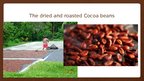

Step #1: Roasting and Winnowing the Cocoa

The first thing that chocolate manufacturers do with cocoa beans is roast them.

Step #2: Grinding the Cocoa Nibs

Grinding is the process by which cocoa nibs are ground into " cocoa liquor", which is also known as unsweetened chocolate or cocoa mass.

Step #3: Blending Cocoa liquor and molding Chocolate

After the mixing process, the blend is further refined to bring the particle size of the added milk and sugar down to the desired fineness.

The Cocoa powder or 'mass' is blended back with the butter and liquor in varying quantities to make different types of chocolate or couverture.

The basic blends with ingredients roughly in order of highest quantity first are as follows:

Milk chocolate

sugar

milk or milk powder

cocoa powder

cocoa liquor

cocoa butter

Lethicin and Vanilla

…

Chocolate is a key ingredient in many foods such as milkshakes, candy bars, cookies and cereals. Chocolate production starts with harvesting coca in a forest. Cocoa comes from tropical evergreen Cocoa trees, such as Theobroma Cocoa, which grow in the wet lowland tropics of Central and South America, West Africa. Step #1: Plucking and opening the Pods Cocoa beans grow in pods that sprout off of the trunk and branches of cocoa trees. The pods are about the size of a football. The pods start out green and turn orange when they're ripe. When the pods are ripe, harvesters travel through the cocoa orchards with machetes and hack the pods gently off of the trees. Machines could damage the tree or the clusters of flowers and pods that grow from the trunk, so workers must be harvest the pods by hand, using short, hooked blades mounted on long poles to reach the highest fruit. After the cocoa pods are collected into baskets ,the pods are taken to a processing house. Here they are split open and the cocoa beans are removed. Pods can contain upwards of 50 cocoa beans each. Fresh cocoa beans are not brown at all, they do not taste at all like the sweet chocolate they will eventually produce.